Snap head rivet length formula

The general formula for calculating the required length of a snap head rivet is L = S + A, where L is the total rivet length, S is the sum of the thicknesses of the materials being joined (the "grip"), and A is the allowance, which is the additional length needed for forming the rivet head, typically 1.5 times the rivet shank diameter (D). Thus, the formula is often expressed as L = S + 1.5D.

Breaking Down the Formula

-

L = S + A: This is the fundamental formula for calculating the necessary rivet length.

-

S (Sum of thicknesses/grip): This is the total combined thickness of all the materials you are joining together with the rivet.

-

A (Allowance): This is the extra length required to form the second head on the rivet after it's inserted through the materials.

-

A common standard for this allowance is 1.5 times the rivet shank diameter (D).

Therefore, the full formula is:

-

L = (Thickness of Material 1 + Thickness of Material 2 + ...) + (1.5 x Diameter of Rivet Shank)

Example

-

Measure the material thicknesses: Let's say you are joining two pieces of metal with thicknesses of 0.125 inches each (S = 0.125 + 0.125 = 0.250 inches).

-

Determine the rivet diameter: The rivet diameter (D) should be approximately three times the thickest sheet. In this case, if your thickest sheet is 0.125 inches, you'd look for a rivet with a diameter around 0.375 inches.

-

Calculate the allowance: A = 1.5 x 0.375 inches = 0.5625 inches.

-

Add the grip and allowance: L = 0.250 inches + 0.5625 inches = 0.8125 inches. You would then select a standard rivet length closest to, but not less than, this calculated length.

Key Considerations

-

The allowance of 1.5D is a common guideline, but the exact allowance can vary depending on the specific application, materials, and the manufacturer's recommendations.

-

Always ensure the calculated length corresponds to a standard available rivet size.

-

For multiple layers, add the thickness of all layers to find the total grip (S).

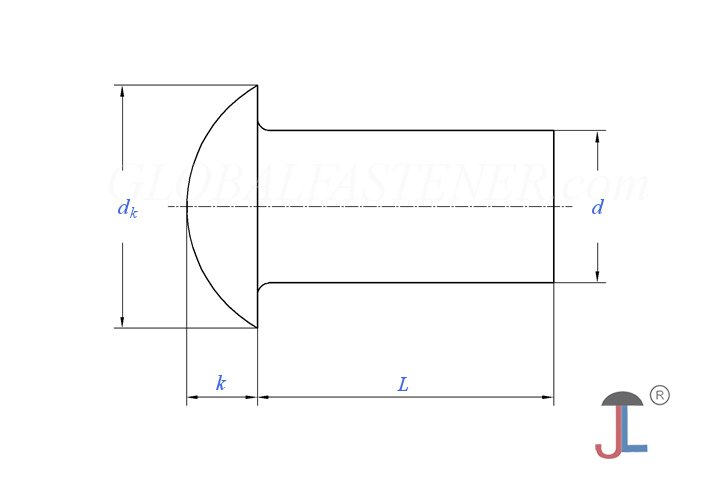

Snap Head Rivet Diagram