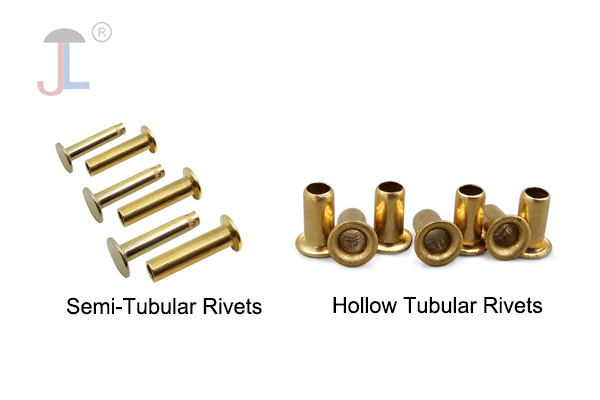

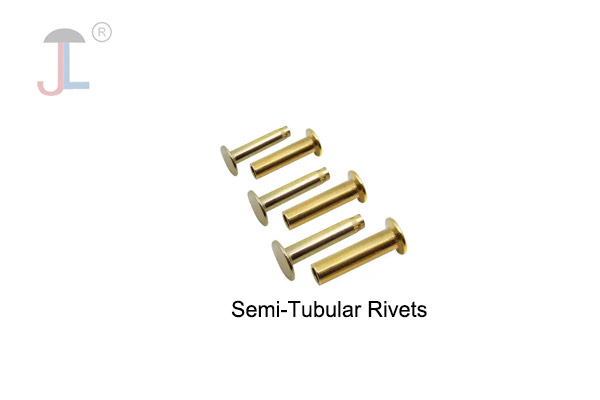

Semi-Tubular Rivets

Also known as hollow rivets.Have a manufactured head on one end and a shallow, tubular shank hole on the other.

The shank hole depth is less than 112% of the shank diameter.

Require less force to install compared to solid rivets.

Can be fastened to a tight or loose fit depending on the application.

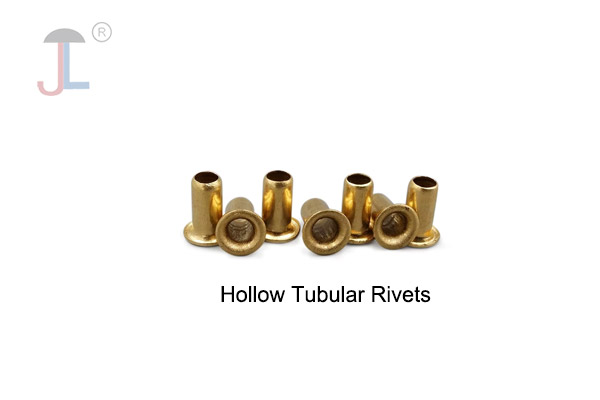

Hollow Tubular Rivets

Also known as full tubular rivets.Have a manufactured head on one end and a deeper, tubular shank hole on the other.

The shank hole depth is equal to or greater than 112% of the shank diameter.

May be weaker than semi-tubular rivets.

Used for fastening thin sheets of material like plastics, leather, sheet metal, and pivot points when movement is necessary.

Need reliable fastening for heavy-duty projects? Our solid brass rivets offer unmatched strength and durability.