Required Tools

- Rivet gun or pneumatic riveting tool

- Drill with appropriate bit size

- Deburring tool

- Measuring tools

- Safety equipment (gloves, eye protection)

Material Preparation: Ensure materials to be joined are clean and properly aligned

Hole Drilling: Create a hole slightly larger than the rivet diameter (typically 0.004" larger)

Deburring: Remove any burrs or sharp edges from the drilled hole

Rivet Selection: Choose the appropriate rivet length (grip range should match material thickness)

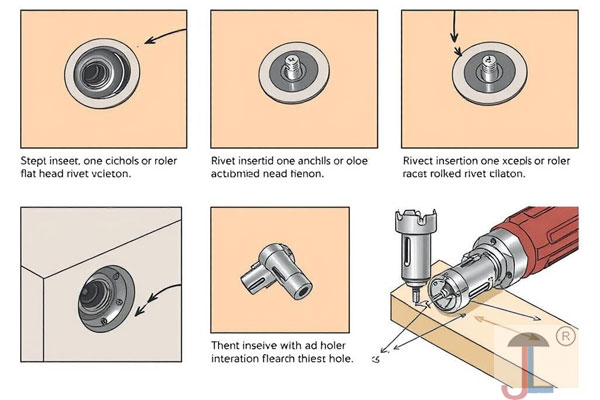

Rivet Insertion: Insert the rivet through the pre-drilled hole

Tool Positioning: Place the riveting tool over the rivet tail

Rivet Setting: Apply consistent pressure until the rivet is fully set

Inspection: Verify proper installation with flush head and secure connection

Hole Drilling: Create a hole slightly larger than the rivet diameter (typically 0.004" larger)

Deburring: Remove any burrs or sharp edges from the drilled hole

Rivet Selection: Choose the appropriate rivet length (grip range should match material thickness)

Rivet Insertion: Insert the rivet through the pre-drilled hole

Tool Positioning: Place the riveting tool over the rivet tail

Rivet Setting: Apply consistent pressure until the rivet is fully set

Inspection: Verify proper installation with flush head and secure connection

Pro Tip: Material Thickness Consideration

When selecting flat head rivets, ensure the grip length is appropriate for the combined thickness of materials being joined. The ideal rivet length should be equal to the material thickness plus 1.5 times the rivet diameter.