To install round head solid rivets, follow these detailed steps:

-

Prepare the Materials and Tools

-

Drill holes in the materials to be joined, ensuring the hole diameter matches the rivet shaft size.

-

Gather tools such as a hammer or mallet, a rivet setting tool or bucking bar, a rivet anvil (a hard surface with a dimple for the rivet head), and optionally a rivet press or pneumatic rivet gun for easier installation.

-

-

Create a Dimple for the Rivet Head (Optional but Recommended for Round Heads)

-

Use progressively sized drill bits to create a round-bottomed dimple on the surface where the rivet head will sit. This helps preserve the round shape of the rivet head when setting it.

-

-

Insert the Rivet

-

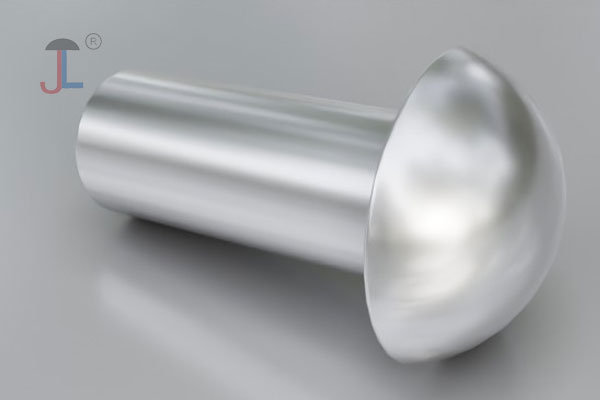

Align the two pieces to be joined and push the rivet shaft through the pre-drilled holes from the side where you want the finished round head to appear.

-

Make sure there are no burrs or debris under the rivet head or between the materials.

-

-

Cut the Rivet Shaft to Length

-

Hold the pieces tightly together and cut the rivet shaft so that about 1/16 inch (approximately 1.5 mm) protrudes beyond the back surface. If cut too short, replace the rivet and try again.

-

-

Set the Rivet

-

Place the rivet head into the dimple on the rivet anvil (head side down on the flat side of the anvil).

-

Position the bucking bar or rivet setting tool on the protruding rivet shaft end.

-

Using a hammer or mallet, strike the rivet shaft end to mushroom it out and form a second head, securing the materials tightly together. Continue hammering until the rivet shaft is flush and the mushroomed end is uniform and even around the circumference.

-

If using a rivet setting tool, align the concave end of the tool on the rivet and strike with a hammer repeatedly until set.

-

-

Alternative Installation Methods

-

For larger or steel rivets, heating the rivet red hot before installation can help in forming the mushroomed end more easily.

-

Pneumatic rivet tools or rivet presses can simplify the process, especially for multiple rivets, by providing consistent impact force.

-

-

Final Inspection

-

Ensure the rivet heads are smooth, round, and flush with the material surfaces.

-

The joint should be tight with no movement between the materials.

-

This method ensures a strong, durable joint with a neat round head finish on the rivet. Using the right tools like a rivet anvil with a dimple and a bucking bar or rivet setter is key to a professional result.