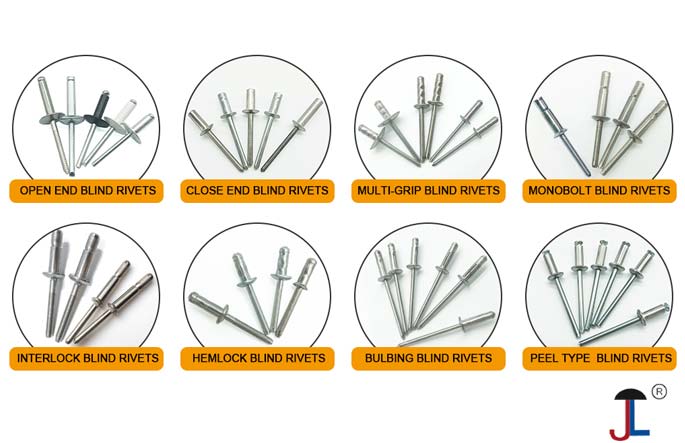

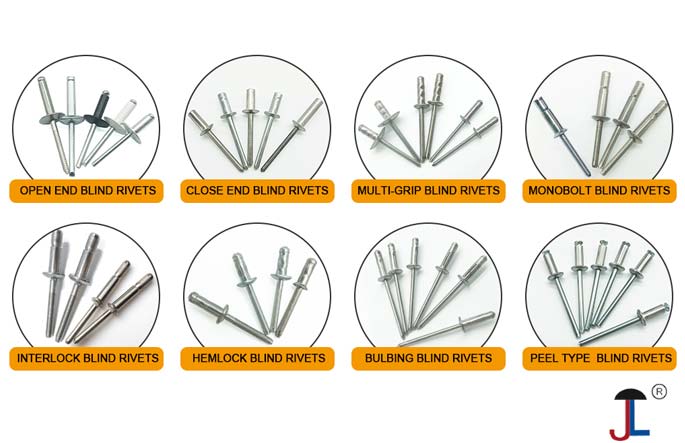

Blind rivets are categorized by their head type and special features, including: Standard (Open-End), Closed-End (Sealed), Multi-Grip (for varying material thicknesses), Peel (for soft materials), Grooved (for grip and vibration resistance), and Structural (for high-strength, critical applications).Other variations include Colored, Large Head, Countersunk Head, and specialized types like Monobolt and Tri-Grip.

Common Types of Blind Rivets

- Standard Blind Rivets (Open-End): The most common and least expensive type.

- Closed-End Rivets: These are designed to seal tightly, preventing liquid and air from passing through.

- Multi-Grip Rivets: Feature a wider grip range, allowing a single rivet to accommodate multiple material thicknesses.

- Peel Rivets: These rivets have four petals that bend outward on the back side to cover a larger surface area, ideal for soft materials like plastic or rubber.

- Grooved Rivets: Have a ridged or grooved body that expands when installed, creating a robust and vibration-resistant joint.

- Structural Blind Rivets: High-strength rivets with a locking stem that creates a watertight and vibration-resistant bond, suitable for critical applications.

Specialty & Other Blind Rivets

- Drive-Type Rivets: A small mandrel on the rivet is driven with a hammer to install it.

- Large-Head Rivets: Offer a larger surface area, providing extra fastening security.

- Countersunk Head Rivets: Have a specific angle on the head to sit flush with the material, creating a smooth finish.

- Colored Rivets: Available in various colors to match or conceal them for aesthetic purposes, often used in automotive applications.

- Tri-Grip Rivets: These have three legs that split behind the workpiece to secure the rivet.

- High-Performance Rivets: Offer high strength and sustainability for various applications, such as attaching signs or joining sheet materials.