-

Solid Rivets:

-

Installation: Solid rivets require access to both sides of the material being fastened. The rivet is placed in a hole, and the rivet's tail is then deformed (typically by hammering or using a rivet gun) to form a strong, permanent bond.

-

Design: Solid rivets are made of a single piece of material and are often used in situations where high strength is required.

-

Applications: They are common in industries like aerospace, automotive, and construction, especially in high-stress applications.

-

-

Blind Rivets:

-

Installation: Blind rivets are designed to be installed from one side only, making them ideal for situations where access to the rear side of the material is not possible. A tool is used to pull the mandrel (the central pin) through the rivet, expanding the rivet body to secure the materials.

-

Design: Blind rivets consist of a hollow body and a mandrel. Once installed, the mandrel breaks off, leaving behind a secure fastening.

-

Applications: Blind rivets are widely used in general manufacturing, construction, and automotive industries where access to both sides of the material is limited or impractical.

-

solid rivets need access to both sides for installation and are typically stronger, while blind rivets can be installed from one side and are more versatile for situations with limited access.

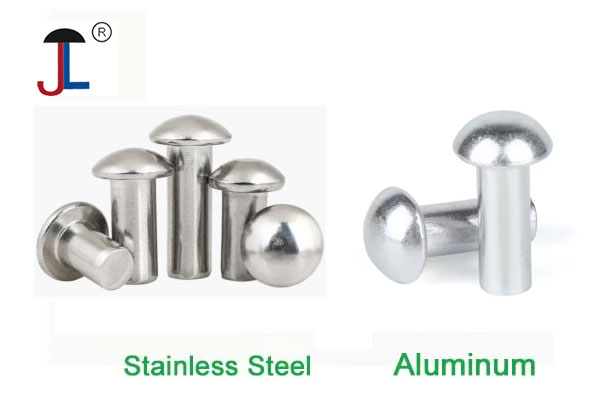

⚙️ High-Performance Stainless Steel Rivets for Heavy Applications