When it comes to fastening solutions, not all rivets are created equal. Among the many types, countersunk head rivets stand out for their ability to provide both structural strength and a sleek, flush finish. But what exactly makes them so versatile, and where are they commonly used? This blog dives deep into the practical applications of countersunk head rivets and why they are a staple in many industries.

Countersunk Rivet Definition

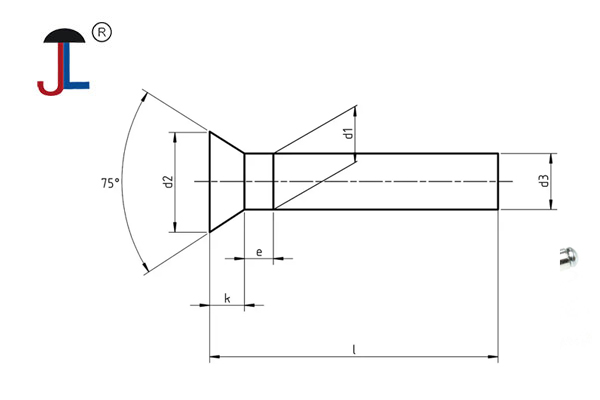

Countersunk head rivets are mechanical fasteners with a conical head designed to sit flush with or below the surface of the materials being joined. Unlike standard rivets, their design eliminates protrusions, which can be critical in applications where smooth surfaces are required for aesthetic, aerodynamic, or safety reasons.

Primary Uses of Countersunk Head Rivets

-

Creating a Flush Surface

The main advantage of countersunk rivets is their ability to produce a flat surface after installation. This is particularly useful in metal sheets, panels, and decorative applications, where protruding fasteners could interfere with function or design. -

Structural Connections in Transportation

Countersunk rivets are extensively used in the aerospace and automotive industries. In aircraft, for example, they are employed on fuselage panels and wing skins to reduce drag and ensure smooth airflow. Similarly, in high-performance automotive applications, flush surfaces are crucial for both safety and aerodynamics. -

Shipbuilding and Marine Applications

In marine environments, countersunk rivets provide strong, corrosion-resistant joints while ensuring that deck surfaces and hull panels remain smooth. This prevents water accumulation and reduces wear over time. -

Furniture and Decorative Hardware

Beyond industrial use, countersunk rivets are popular in furniture assembly and interior design, offering a neat, finished look without visible fastener heads disrupting the surface aesthetics. -

Electronics and Appliance Assembly

Small countersunk rivets are used in electronics and consumer appliances to secure casings and components while keeping surfaces flush. This improves both appearance and functionality, preventing cables or components from being snagged.

Advantages of Using Countersunk Head Rivets

- Flush Finish: Prevents protrusions and enhances product aesthetics.

- Enhanced Safety: Reduces the risk of catching or scratching on protruding fasteners.

- Versatility: Can join a wide range of materials including aluminum, steel, and composites.

- Strength: Provides reliable mechanical fastening for both structural and non-structural applications.

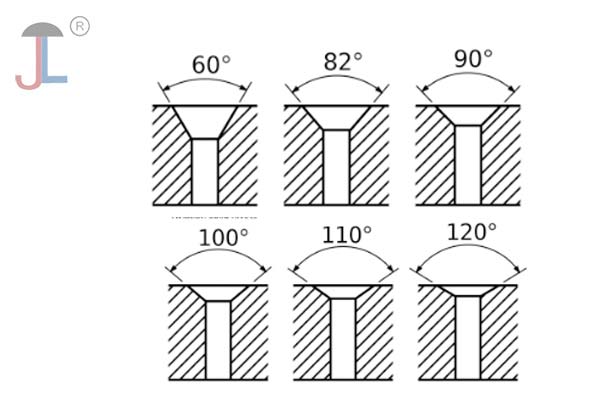

- Customizable: Countersunk rivets can be produced in different diameters, lengths, materials, and head angles (60°, 82°, 90°, 100°, 110°, 120°) to suit specific engineering requirements.

Industries Benefiting from Countersunk Rivets

- Aerospace & Aviation – flush exterior panels, fuselage, and wing assemblies.

- Automotive – car body panels, dashboards, and aerodynamic components.

- Shipbuilding – decks, hulls, and watertight panels.

- Construction & Metal Fabrication – steel structures, cladding, and sheet metal applications.

- Furniture & Interior Design – decorative assemblies requiring a seamless look.

- Electronics & Appliances – internal fastenings where surface finish is critical.

Conclusion: Customization Is Key

Countersunk head rivets are more than just simple fasteners—they combine functionality, strength, and aesthetic appeal. For manufacturers and designers, having the option to customize size, material, and head angle ensures that the rivet perfectly meets the needs of any project. Whether it’s aerospace, automotive, marine, or decorative applications, countersunk rivets provide a reliable, sleek, and efficient fastening solution.