When it comes to high-quality fastening solutions, countersunk rivets play a vital role in ensuring both strength and aesthetics. But one key factor that often gets overlooked is the rivet head angle. Understanding this element can make the difference between a strong, flush installation and one that looks uneven or fails under stress.

What Is a Countersunk Rivet Angle?

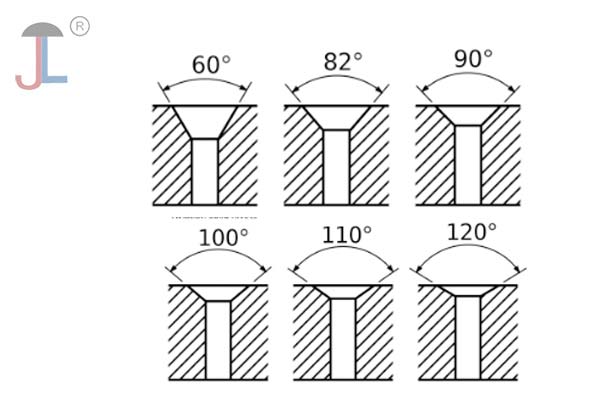

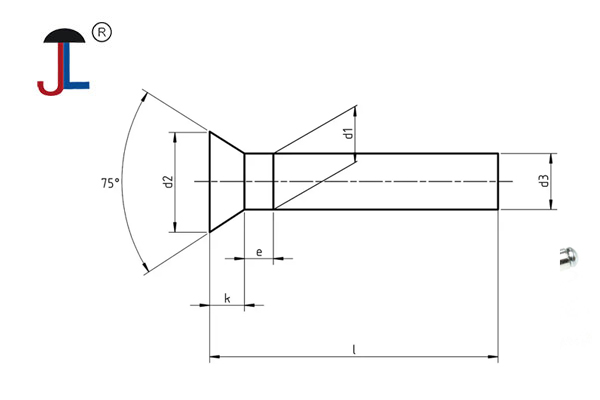

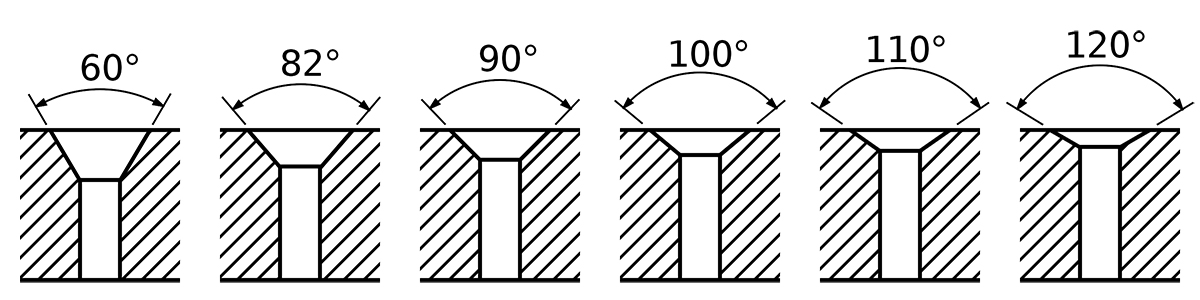

The countersunk rivet angle is the angle formed by the conical head of the rivet. It determines how the rivet sits in the material once installed. Unlike dome or pan-head rivets that protrude above the surface, countersunk rivets are designed to sit flush, creating a smooth, even finish.

Common angles include 60°, 82°, 90°, 100°, 110°, and 120°, each suited to different applications. The correct angle selection depends on factors such as material thickness, load requirements, and design preferences.

Why Rivet Angle Matters

-

Flush Installation:

Using the proper angle ensures the rivet head sits perfectly flush with the surface, providing a clean, professional appearance. -

Load Distribution:

The rivet head angle affects how the load spreads across the material. A proper match prevents stress concentration, reducing the risk of cracks or deformation. -

Material Compatibility:

Different materials react differently to rivet installation. Softer metals or plastics may require shallower angles, while harder metals often need steeper angles for a secure fit. -

Aesthetic Considerations:

In visible applications, the right countersunk angle ensures a seamless look, making your product not only functional but also visually appealing.

Choosing the Right Countersunk Rivet Angle

Selecting the correct angle is a mix of science and experience. Here are some general guidelines:

- 60° & 82°: Often used in aerospace and automotive applications where precision and lightweight materials are critical.

- 90° & 100°: Ideal for general industrial use with medium-thickness materials.

- 110° & 120°: Best suited for thicker materials, heavy-duty constructions, or decorative finishes requiring a shallow head appearance.

Always consult material specifications and load requirements before choosing an angle, as the wrong selection can compromise both performance and safety.

Customization Options for Countersunk Rivets

At Jiliang Rivets, we understand that no two projects are the same. That’s why we offer custom countersunk rivet solutions, including:

- Custom angles tailored to specific material thicknesses

- Special head finishes for aesthetic or functional purposes

- Personalized sizes and lengths to meet unique engineering requirements

Whether you’re working on aerospace components, automotive assemblies, or architectural fixtures, our team can help design rivets that perfectly fit your project needs.

Conclusion

The countersunk rivet angle is more than just a technical specification—it’s a crucial factor that affects the strength, safety, and appearance of your fastening solution. By understanding the different angles and choosing the right one for your material and load requirements, you can achieve a perfectly flush, strong, and professional finish every time.

Need a custom rivet design? Jiliang Rivets specializes in tailored solutions to match your exact specifications, ensuring reliable performance and a flawless installation.