Semi-tubular rivets are a common type of fastener used in various applications, from light fixtures to luggage, where a strong, permanent joint is needed, often allowing for some movement (pivot points). They are distinguished by a shallow hole at the tip of the rivet, which makes them easier to install than solid rivets.

Here's a breakdown of how to install semi-tubular rivets, including common tools and methods:

Understanding Semi-Tubular Rivets

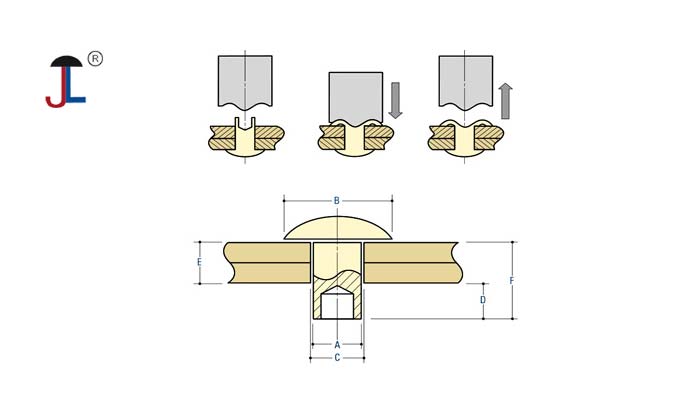

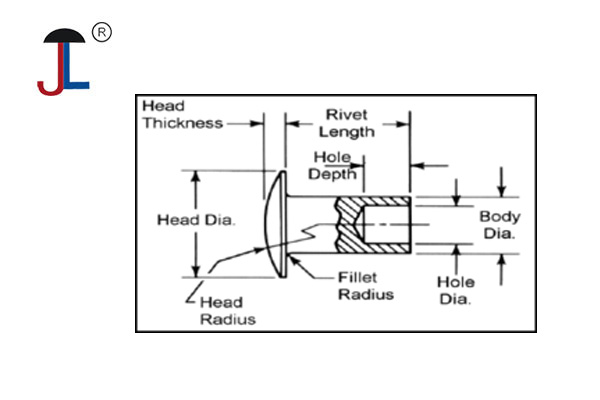

- Design: They have a cylindrical body with a hollow interior on one end. The "hollow" portion is designed to roll or flare outward when force is applied, creating a secure clinch.

- Materials: Common materials include steel, brass rivet, copper rivet, stainless steel rivets, and aluminum rivets.

-

Advantages:

- Require significantly less force to install compared to solid rivets.

- Efficient for mass production.

- Provide a strong and permanent joint.

Installation Methods and Tools

The method you choose will depend on the scale of your project and the tools available.

-

Manual Rivet Setter (Hand Tool) This is a common method for small-scale projects or when a dedicated machine isn't practical.

- Tools: A rivet setter (also known as a rivet peening tool or flaring tool) and a hammer. Some rivet setters come as a kit with different dies for various rivet sizes. A bucking bar (a heavy piece of metal) can also be used for support on the tail end.

-

Steps:

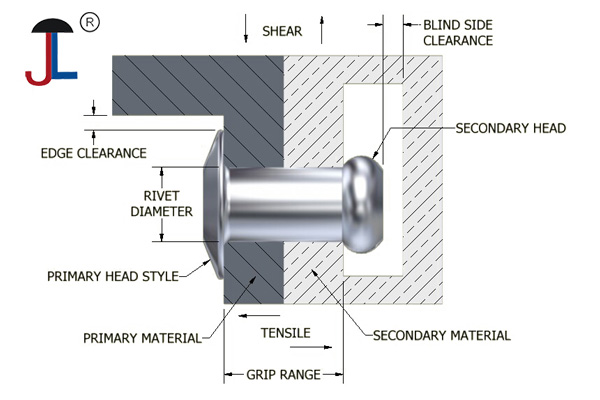

- Prepare the materials: Drill pilot holes in the materials you want to join. The hole diameter should be slightly larger than the rivet's shank diameter (typically 0.010" to 0.015" larger).

- Insert the rivet: Push the semi-tubular rivet through the aligned holes from the "head" side.

- Position the rivet setter: Place the rivet setter over the hollow end (the "buck-tail") of the rivet. The setter typically has a concave or shaped end designed to roll the rivet.

- Hammer the rivet: Strike the rivet setter with a hammer. The force will cause the hollow end of the rivet to flare outward, forming a second head and clinching the materials together.

- Inspect: Check that the rivet is flush and secure, and that the materials are tightly joined.

-

Manual Squeezer / Rivet Gun These tools use a lever or squeeze mechanism to apply force.

- Tools: A manual rivet gun/squeezer.

-

Steps:

- Prepare and insert: Drill holes and insert the rivet as described above.

- Position the gun: Place the jaws of the rivet gun over the rivet, with one jaw supporting the head and the other pressing on the hollow end.

- Squeeze: Squeeze the handles of the rivet gun. This applies pressure, causing the hollow end to deform and clinch the rivet.

- Inspect: Verify the rivet is properly set.

-

Specialized Riveting Machines (for production) For high-volume manufacturing, specialized machines are used:

- Pneumatic Squeezers: Use compressed air for faster and more consistent results.

- Kick Presses: Foot-operated machines that provide controlled force.

- Impact Riveters: Use an impact force to set the rivets.

- PLC-Controlled Robotics: Fully automated systems for high-speed, precise riveting.

Important Considerations for Successful Installation:

-

Rivet Size: Use the correct rivet diameter and length for your materials.

- Shank Diameter: Should be appropriate for the material thickness (often a 1:1 to 1:3 ratio for metal, closer to 1:1 for plastic).

- Hole Size: The pre-drilled hole should be slightly larger than the rivet shank to allow for easy insertion without damaging the rivet or part.

- Shank Length / Clinch Allowance: The rivet needs enough length (stick-out) beyond the material stack-up to properly form the clinched end. This is typically 50-55% of the shank diameter. If too short, it won't clinch; if too long, the parts may not be tight.

- End-Hole Depth: The depth of the hollow portion of the rivet is crucial for proper forming.

- Support: Always support the head of the rivet on a solid surface or with an appropriate die to prevent bending or damage during installation.

- Practice: If you're new to riveting, practice on scrap material to get a feel for the tools and the amount of force needed.

By following these guidelines and using the appropriate tools, you can successfully install semi-tubular rivets for a variety of projects.