Design and Structure

-

Solid Rivets:

Made from a single, solid piece of metal. Their fully dense structure provides high strength and durability, making them well-suited for applications that experience heavy loads and high stress. -

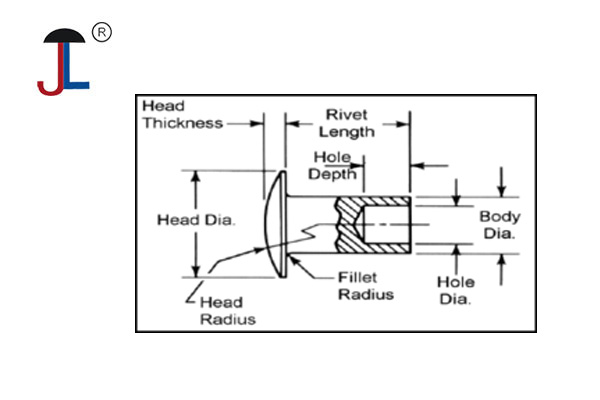

Tubular Rivets:

These rivets feature a hollow, tube-like design. The central void reduces material weight and can simplify installation, but it may also mean they have slightly lower load-bearing capacity compared to solid rivets.

Installation Process

-

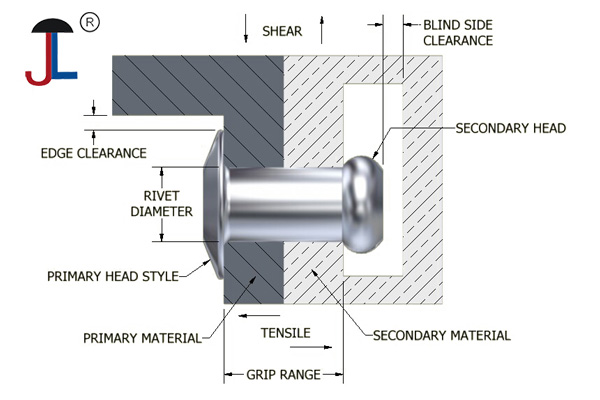

Solid Rivets:

Typically installed by heating and then hammering or pressing. This process deforms the rivet’s tail, forming a head that secures the joint. The installation requires significant force and often specialized equipment. -

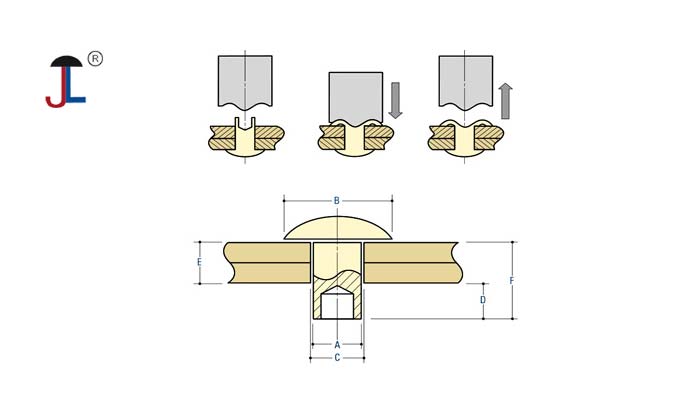

Tubular Rivets:

Usually installed using a setting tool that compresses the hollow section, causing the rivet to expand and lock into place. This process can be less labor-intensive and is often preferred in applications where speed or ease of installation is critical.

Applications and Performance

-

Solid Rivets:

Chosen for structural joints where maximum strength and fatigue resistance are essential. They are common in heavy construction, aerospace, and other high-stress environments. -

Tubular Rivets:

Often used in lighter applications or where the benefits of reduced weight and easier installation outweigh the need for the ultimate in load capacity. They can be found in automotive panels, electronics, and similar areas where moderate strength is acceptable.

In summary, while both types secure materials effectively, the choice between solid and tubular rivets depends on the specific strength requirements, weight considerations, and installation conditions of the project.

? Premium Stainless Steel Rivets – Quality You Can Trust