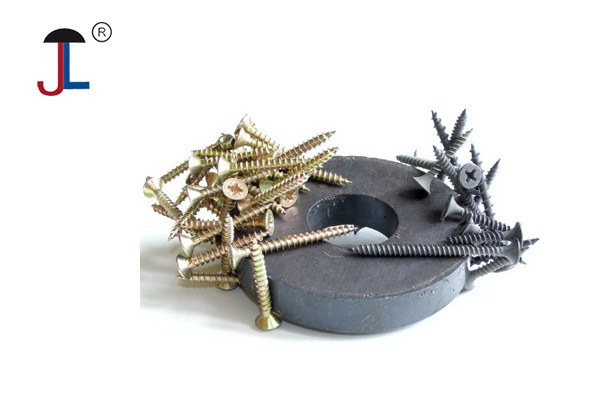

It depends on the grade of stainless steel you’re using:

-

Austenitic grades (300‑series, e.g. 304, 316)

-

Chemically non‑magnetic in the annealed (soft) condition.

-

Common for screws (often sold as “18‑8” stainless).

-

However, cold‑working (thread‑rolling, bending) can introduce a small amount of martensite, so a magnet may “stick,” albeit weakly.

-

-

Ferritic grades (400‑series, e.g. 430)

-

Always magnetic.

-

Less corrosion‑resistant than austenitics; less common for general‑purpose screws.

-

-

Martensitic grades (also 400‑series, e.g. 410, 420)

-

Hardenable by heat treatment; magnetic in both annealed and hardened conditions.

-

Often used where higher strength is needed (e.g. security or cut‑resistant screws).

-