1. Heat-Induced Oxide (Torch Method)

Heating stainless steel screws uniformly until they glow orange in a neutral-flame oxy-acetylene torch drives off chromium and nickel oxides, leaving behind a thin, hard black oxide layer roughly 0.002 in thick.Allow the screws to cool naturally to lock in the coloration, then polish lightly with fine steel wool or a Scotch-Brite pad to enhance the shine and smoothness.2. Hot Chemical Blackening (High-Temperature Black Oxide)

Industrial black-oxide lines immerse parts in proprietary oxidizing solutions heated to 120–130 °C, forming a compact oxide film (~0.1 µm) that does not change part dimensions and improves corrosion resistance.A simple laboratory recipe cited in the Metal Finishing Guidebook uses sulfuric acid (180 parts) with water (200 parts) and potassium dichromate (50 parts) at 210 °F (99 °C) for uniform blackening.3. Cold Chemical Blackening (Room-Temperature)

Caswell SSB370: Use full-strength or dilute up to 1 part concentrate to 3 parts water to blacken stainless at room temperature; no sealer required and yields a dark gray-black finish.EPI Insta-Blak SS-370 GEL: Clean parts, then apply full-strength gel with a swab, brush, or sponge for 1–10 minutes; rinse and repeat until uniform.

Cold Bluing Salts: Copper- or selenium-based cold bluing solutions will blacken stainless with time and minimal heat, though results may lack the sheen of hot processes.

Quick Kits: Cold-bluing kits require only thorough degreasing and application at room temperature, making them very accessible for DIY.

4. Alternative Surface Coatings

Beyond oxide conversion, stainless screws can be:Powder Coated for thick, uniform coverage.

Electroplated in black nickel or black chrome for high wear resistance.

PVD-Coated (e.g., titanium nitride variants) in a vacuum for premium durability and color control.

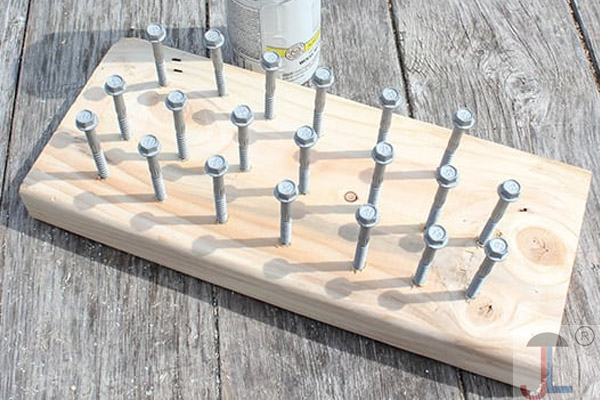

Step-by-Step DIY Cold Blackening

Clean: Degrease thoroughly with isopropyl alcohol or a proprietary stainless cleaner. Rinse until water sheets off (“water break” test).Remove Oxide/Rust: Lightly abrade with steel wool or Scotch-Brite to expose bare metal.

Blacken:

SSB370: Dip or brush on full-strength or 1:3 diluted solution; wait 2–5 minutes, then rinse.

Insta-Blak SS-370: Swab on gel, rub gently for up to 10 minutes, rinse, and repeat until desired darkness is achieved.

Rinse & Dry: Use clean water, then air-dry or wipe with lint-free cloth.

Seal (Optional): Apply a light coat of mineral oil, wax, or lacquer to lock in the finish and boost corrosion resistance.

Safety & Tips

Always wear chemical-resistant gloves, eye protection, and work in a well-ventilated area to avoid fumes.Test on a scrap screw to dial in timing and dilution ratios before treating your final parts.

Avoid aggressive acids or high heat near threaded areas if you need precise fit tolerances.