Factors Influencing Corrosion Resistance

-

Alloy Grade: The corrosion resistance of stainless steel screws varies by grade. For example, 304 stainless steel offers good resistance in dry environments, while 316 stainless steel, which includes molybdenum, is better suited for marine or coastal areas due to its enhanced resistance to chloride-induced corrosion .

-

Environmental Conditions: Extreme conditions, such as exposure to high levels of chlorides (e.g., saltwater), acidic environments, or high humidity, can compromise the protective oxide layer, leading to rust formation over time.

-

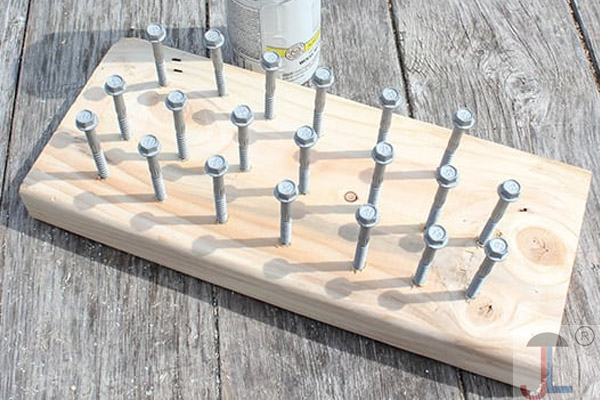

Mechanical Damage: Physical damage to the screw, such as scratches or abrasions, can expose the underlying metal to corrosive elements, potentially leading to rust .

Recommended Reading: