Tensile Strength Comparison:

-

Stainless Steel Screws: Typically have a tensile strength ranging from 100,000 to 150,000 PSI, depending on the grade and alloy used.

-

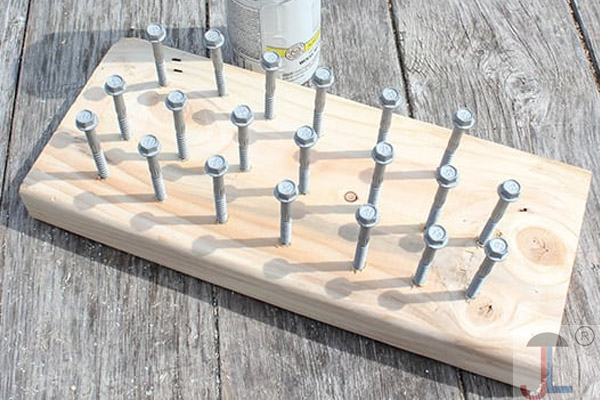

Zinc-Coated (Galvanized) Screws: Usually have a tensile strength of around 62,000 PSI, as they are often made from Grade 2 steel, which is softer and less durable.

Corrosion Resistance:

-

Stainless Steel: Naturally resistant to rust and corrosion due to its chromium content, making it ideal for harsh environments such as marine, coastal, or industrial settings.

-

Zinc-Coated Screws: The zinc coating provides corrosion resistance, but if the coating is scratched or worn off, the underlying steel can rust.

Applications:

-

Stainless Steel Screws: Best suited for applications requiring high strength and resistance to corrosion, such as marine construction, outdoor furniture, and structural supports.

-

Zinc-Coated Screws: Suitable for indoor applications or areas with minimal exposure to moisture, where cost-effectiveness is a priority.

Conclusion:While stainless steel screws offer superior strength and corrosion resistance, they come at a higher cost. Zinc-coated screws are more affordable and adequate for less demanding applications. The choice between them should be based on the specific requirements of your project, considering factors like environmental exposure, load-bearing needs, and budget constraints.