Why Galvanic Corrosion is a Concern

Dissimilar Metals:Stainless steel and aluminum have different electrochemical potentials, meaning they are not compatible.

Electrolyte:

Saltwater acts as an electrolyte, facilitating the flow of electrons between the dissimilar metals.

Corrosion:

Aluminum is more anodic than stainless steel, meaning it will corrode (dissolve) more readily when in contact with the stainless steel in the presence of an electrolyte.

How to Minimize Galvanic Corrosion

1. Use Marine-Grade Fasteners:Choose stainless steel fasteners specifically designed for marine applications, such as 316 stainless steel, as they offer better compatibility with aluminum.

2. Separate Metals:

Use a barrier, like a layer of Tef-Gel or a piece of plastic, between the stainless steel screw and the aluminum to prevent direct contact.

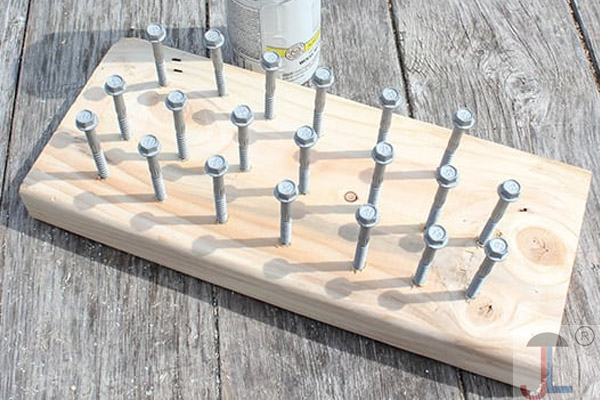

3. Reduce Contact Area:

Keep the contact area between the stainless steel and aluminum small to minimize the potential for corrosion.

4. Keep it Dry:

Avoid areas where the dissimilar metals will be constantly submerged in saltwater.

5. Consider Aluminum Fasteners:

In some cases, using aluminum fasteners on stainless steel might be a better option, as aluminum is less likely to corrode than stainless steel.

In summary: While stainless steel screws can be used on aluminum boats, you must be mindful of galvanic corrosion and take steps to prevent it by using the right materials, creating barriers, and minimizing contact area.