Chemical Composition Differences

Both 305 and 316 stainless steels are austenitic grades with similar chromium content—typically around 18%—which imparts general corrosion resistance and formability; however, they differ significantly in nickel and molybdenum content.

Grade 305 stainless steel contains approximately 10–12% nickel, with carbon limited to 0.08% maximum, and no intentional molybdenum addition, which contributes to its high ductility and formability.

In contrast, Grade 316 stainless steel typically includes 10–14% nickel and 2–3% molybdenum, along with similar chromium levels; the molybdenum addition significantly enhances resistance to chloride-induced corrosion.

Corrosion Resistance

316 stainless steel exhibits superior pitting and crevice corrosion resistance in chloride environments compared to 305, thanks to its molybdenum content, making it ideal for marine and chemical applications.

While 305 offers good general corrosion resistance similar to 304, it lacks the additional protection against chlorides and acids that 316 provides.

Mechanical and Physical Properties

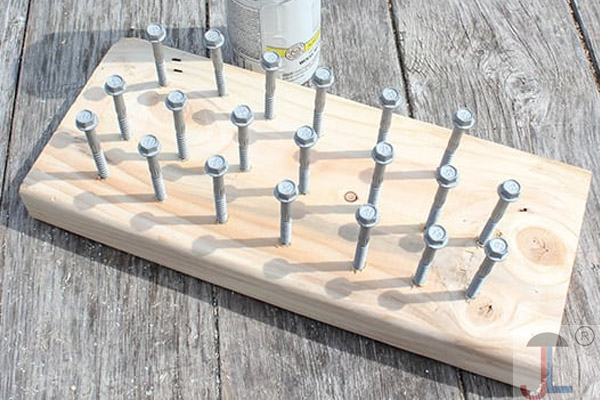

Due to its high nickel content and low work-hardening rate, 305 stainless steel screws have excellent ductility and can be drawn, spun, and headed easily, benefiting manufacturing processes like deep drawing.

316 stainless steel fasteners exhibit higher tensile and yield strengths compared to 305, providing better load-bearing capacity in structural applications.

Typical Applications

305 stainless steel screws are commonly used in applications requiring extensive forming—such as kitchenware, appliances, and decorative trim—where complex shaping is critical and exposure to harsh environments is minimal.

Conversely, 316 stainless steel screws are favored in marine hardware, chemical processing equipment, and outdoor fixtures where exposure to salt, acids, and high humidity demands high corrosion resistance.

Cost and Availability

Due to the addition of molybdenum, 316 stainless steel is typically priced 20–30% higher than 305, impacting the overall cost of fasteners.

Both grades are widely available from standard fastener suppliers, but 316 may have longer lead times or minimum order quantities in specialized sizes.

In choosing between 305 and 316 stainless steel screws, weigh the environment and mechanical demands of your application: opt for 305 when formability and cost-efficiency in mild conditions are paramount, and select 316 where exposure to chlorides, acids, or high humidity necessitates superior corrosion resistance and strength