Stainless steel screws are far more corrosion‑resistant than plain carbon‑steel ones, but they aren’t 100% immune to “rust.” Here’s why:

-

The chromium oxide “passive” layer

Stainless steel contains at least 10.5% chromium, which reacts with oxygen in the air to form a super‑thin, protective chromium‑oxide film. As long as that layer stays intact, iron in the alloy can’t combine with water and oxygen to form iron‑oxide (“rust”). -

When the passive layer gets compromised

-

Chloride attack: Salt (especially sodium chloride in seawater or road‑salt spray) can break down the protective film, leading to pitting or crevice corrosion.

-

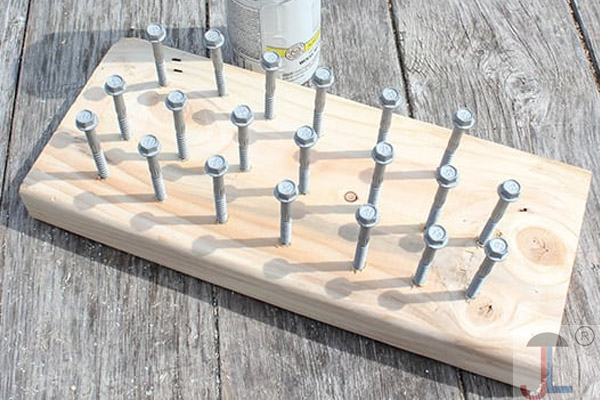

Mechanical damage: Scratches or abrasion can remove the oxide layer faster than it can reform, letting localized rust start.

-

Chemical exposure: Strong acids or bases (e.g., some cleaning agents) can weaken the passive film.

-

-

Grades matter

-

304 stainless (the most common) handles everyday environments well but is more prone to pitting in salty or acidic conditions.

-

316 stainless adds molybdenum, which boosts resistance against chlorides—so it’s the go‑to for marine, pool, or de‑icing salt exposure.

-

-

“Surface rust” vs. true rust

Sometimes you’ll see brownish staining on stainless parts. That’s often iron particles from nearby carbon‑steel brushing against the stainless (for example, a steel wire brush), not the stainless itself corroding. A good passivation or cleaning cycle usually removes those stains. -

Preventing rust on stainless screws

-

Pick the right alloy: Use 316 or even 317 in really aggressive environments.

-

Regular cleaning: Rinse off salt spray or pollutants with fresh water, then wipe dry.

-

Avoid metal cross‑contamination: Use stainless tools when handling stainless fasteners.

-

Passivation treatments: Commercial nitric‑ or citric‑acid baths can restore or strengthen the protective film.

-

Bottom line: under normal indoor or light‑outdoor conditions, a good‐quality stainless‑steel screw will essentially never rust. But if you expose it to harsh chemicals, saltwater, physical damage, or inferior alloys, you can still get pitting and discoloration that resembles rust.