Materials and Tools

You’ll need the following basic supplies:

-

Cleaning Solutions:

- Mild dish soap and warm water

- White vinegar or cola for light rust removal

- Baking soda and water paste for gentle abrasion

- Commercial stainless steel cleaner or Bar Keepers Friend (oxalic-acid based)

-

Mechanical Tools:

- Soft-bristle or nylon brushes (for general cleaning)

- Brass-wire brush (for heavier rust)

- Abrasive pads or Scotch-Brite (non-stainless steel abrasive)

-

Drying & Polishing:

- Lint-free microfiber cloths

- Hair dryer (optional, to ensure moisture-free threads)

- Stainless steel polish or light machine oil for finishing

-

Safety Gear:

- Chemical-resistant gloves and eye protection

Step-by-Step Cleaning Guide

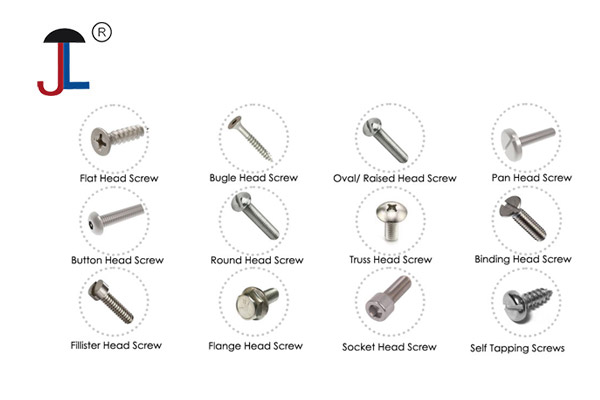

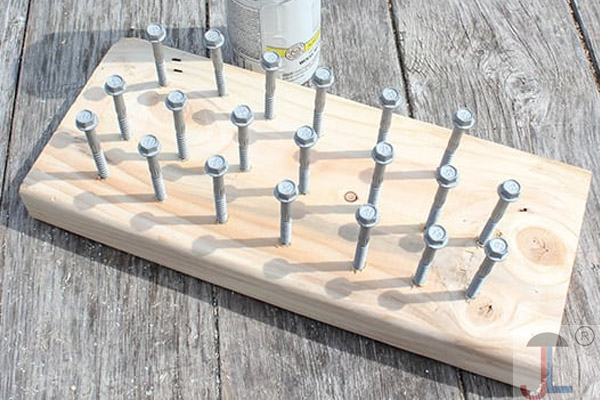

1. Inspection and Preparation

Begin by laying out all nuts and bolts on a clean tray. Visually inspect each piece for signs of deep pitting or structural damage; replace any hardware that is compromised beyond cleaning

2. Degreasing

Mix a few drops of mild dish soap in warm water. Submerge the fasteners and agitate for several minutes to lift surface oils and light grime. For heavy grease, spray a commercial degreaser or brake cleaner, let it penetrate for 10–15 minutes, then brush lightly.

3. Rust Removal Soak

- Vinegar Soak: Place bolts in undiluted white vinegar for 30–60 minutes; the acetic acid dissolves rust and mineral scale.

- Cola Soak (Alternative): An overnight soak in cola leverages phosphoric acid to remove light corrosion.

- Baking Soda Paste: For residual stains, apply a thick paste of baking soda and water, let sit 15 minutes, then scrub gently.

4. Mechanical Scrubbing

After soaking, use a soft-bristle brush for general cleaning, switching to a brass-wire brush or Scotch-Brite pad for stubborn rust spots. Work carefully along threads to preserve integrity.

5. Rinse and Dry

Rinse thoroughly under running water to remove all residues. Shake off excess water and pat dry with a microfiber cloth. For complete moisture removal, blow-dry with a hair dryer or compressed air.

6. Polishing

Apply a small amount of Bar Keepers Friend or a dedicated stainless steel polish with a damp cloth. Rub in the direction of the grain or threads, then buff to a shine with a clean microfiber cloth.

7. Protective Coating (Optional)

To inhibit future corrosion, lightly coat threads and surfaces with machine oil, light mineral oil, or a specialized fastener lubricant. A thin film of WD-40 can also displace moisture but should be wiped off before reassembly in food-contact environments.

Additional Maintenance Tips

- Avoid Galvanic Corrosion: Prevent direct contact between stainless fasteners and dissimilar metals by using rubber or nylon washers.

- Grade Selection: Use 316-grade stainless steel in humid or marine environments; 304-grade suffices for general use.

-

Proper Tools: Employ chrome-plated or stainless-steel tools to avoid introducing iron contamination that can rust.

-

Regular Cleaning: Periodic rinsing with clean water after exposure to corrosive elements (e.g., salt spray) helps preserve the chromium oxide layer.

Safety Precautions

Always work in a well-ventilated area when using acids or commercial cleaners. Wear appropriate gloves, eye protection, and, if spraying solvents, a respirator. Never mix different chemical cleaners (e.g., bleach and ammonia) to avoid hazardous fumes.