Tools and Methods for Cutting Machine Screws

- Wire Strippers with Screw Cutting Holes: Many wire strippers or electrician's pliers have holes sized for common screw threads (e.g., #6-32, #8-32). You thread the screw into the appropriate hole up to the desired length, then squeeze the handles to shear off the excess. This method cuts the screw cleanly without damaging the threads and often cleans up the threads as you back the screw out, leaving a smooth end that won’t catch when threading back into a nut or hole.

- Bolt Cutters: For thicker or tougher machine screws, bolt cutters are very effective. Place one or two nuts on the screw before cutting. After cutting, unscrew the nuts; this action helps restore and clean the threads damaged during cutting. Bolt cutters allow quick cuts with minimal effort and can handle larger screws that wire strippers cannot.

- Hacksaw: A hacksaw is a versatile tool for cutting screws of various sizes. Secure the screw in a vise or clamp, mark the desired length, and saw steadily along the mark. After cutting, file the edges smooth to remove burrs. This method requires more effort and may leave rough edges if not finished properly.

- Angle Grinder or Dremel with Cut-Off Wheel: For larger or very tough screws, an angle grinder with a metal cutting wheel or a Dremel tool with a cut-off wheel can make quick, straight cuts. Always secure the screw in a vise, wear safety gear, and cut slowly to maintain control. After cutting, smooth the edges with a file or grinder disc. Threading a nut on before cutting and unscrewing it afterward helps restore the threads.

Additional Tips to Preserve Threads

- Thread a Nut Before Cutting: Screw one or two nuts onto the screw before cutting. After the cut, unscrew the nuts over the cut end to clean and restore the threads, making it easier to thread the screw into a hole or nut again.

- File or Deburr the Cut End: After cutting, use a metal file or a chamfering tool to smooth rough edges and burrs on the cut end. This prevents thread damage and ensures smooth insertion.

- Secure the Screw Firmly: Use a vise or clamp to hold the screw steady during cutting to ensure a straight, clean cut and to avoid injury.

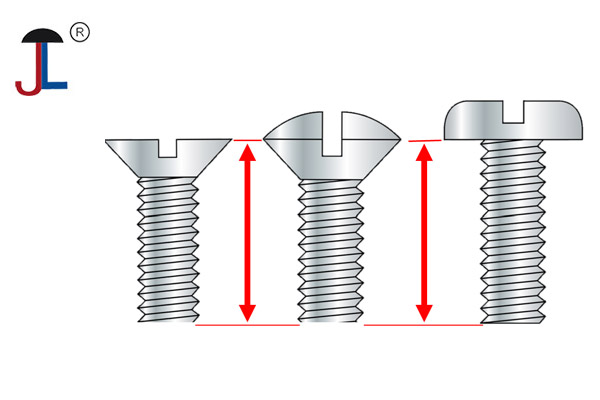

- Measure and Mark: Use a permanent marker to mark the exact length before cutting to ensure precision.

Summary Table of Cutting Methods

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Wire Strippers | Small to medium screws | Clean cut, preserves threads | Limited to smaller screws |

| Bolt Cutters | Medium to large screws | Quick, easy, restores threads with nuts | Requires strength, larger tool |

| Hacksaw | Various sizes | Inexpensive, versatile | Effort-intensive, rough edges possible |

| Angle Grinder / Dremel | Large, tough screws | Fast, precise with steady hand | Requires safety gear, risk of thread damage without nuts |

By using these methods and precautions, you can cut machine screws cleanly and maintain usable threads for reassembly or fastening.