A machine screw is a fastener, similar to a bolt, that's designed to be threaded into a pre-existing, tapped hole or used with a nut. They are typically smaller in diameter (under 0.75 inches, according to the American Society of Mechanical Engineers (ASME)) and have a recessed drive head (like slotted or Phillips) for turning with a screwdriver. Machine screws are fully threaded along their length and are commonly used in various applications like attaching parts in machinery, electronics, and industrial equipment.

Key characteristics of machine screws include:

-

Thread Profile and Size

- Threads are typically standardized (e.g., Unified Thread Standard in the U.S. or ISO metric elsewhere), meaning you’ll see designations like M3 × 0.5 mm (for metric) or 6 –32 (for imperial).

- Because the threads are uniform from head to tip, machine screws do not “bite” into material the way a self‑tapping screw does; they rely on mating with a matching internal thread in a nut or hole.

-

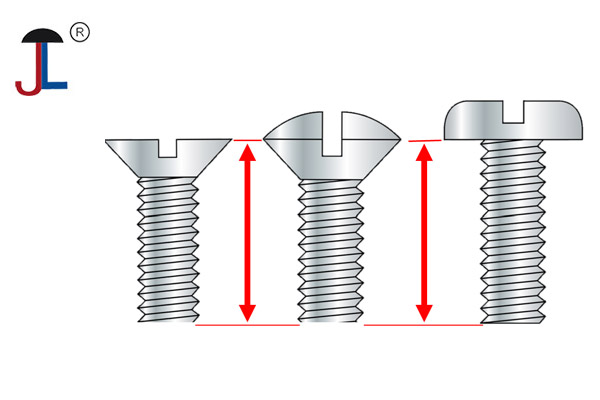

Head Styles and Drive Types

- Common head styles include pan head, flat (countersunk) head, round head, hex head, oval head, and button head. Each style serves a different aesthetic or functional purpose. For example, a flat (countersunk) head sits flush with the surface for a smooth finish, while a hex head allows use of a wrench for higher torque.

- Drive types vary—slotted, Phillips, Pozidriv, Torx, hex socket (Allen), and more—so you can choose a drive that minimizes cam‑out, allows higher torque, or simply matches existing tooling.

-

Materials and Finishes

- Machine screws are made from steel (often zinc‑plated, stainless steel, or alloy steel), brass, aluminum, nylon, and other materials. The choice depends on strength requirements, corrosion resistance, conductivity, and cost.

- Common finishes include black oxide, zinc plating, nickel plating, or anodized coatings (for aluminum screws). Stainless‑steel screws, for example, are prized in marine or medical environments because they resist rust.

-

Typical Applications

- Electronics and Enclosures: Attaching circuit boards, joining metal or plastic panels, closing up electronic housings.

- Machinery and Equipment: Securing components in engines, gearboxes, pumps, or industrial frames—anywhere a securely threaded joint is needed.

- Automotive and Aerospace: Fastening interior trim, brackets, or sensing devices where precise torque and thread engagement are critical.

- Furniture and Fixtures: In higher‑end or modular furniture, machine screws connect metal frames or attach hardware to pre‑drilled, tapped holes.

-

Advantages over Other Fasteners

- Precision and Consistency: Because machine screws and their mating threads are manufactured to tight tolerances, you get uniform clamping force every time.

- Reusability: You can assemble and disassemble machine‑screw joints many times without significant wear, provided the threads aren’t overtightened.

- High–Load Capacity: In metal‑to‑metal joints, a properly sized machine screw can handle substantial shear and tensile loads.

In short, a machine screw is the go‑to fastener whenever you need a precise, strong, and reusable threaded joint in metal (or similarly hard materials). Its fine threads, standard sizing, and variety of head and drive options make it the backbone of countless mechanical, electronic, and industrial assemblies.