machine screws are designed to thread into pre-tapped holes or pair with nuts. Here’s a rundown of their most common uses:

-

Securing Components in Machinery and Equipment

- Engines, Pumps, and Gearboxes: Inside engines or gearboxes, machine screws hold bearing caps, covers, and internal brackets in place. Because these parts undergo vibration and temperature changes, machine screws (often made from stainless steel or alloy steel) ensure a snug, reliable fit that can be loosened for maintenance or rebuilds.

-

Industrial Automation and Robotics: Robotic arms, conveyor rails, and automated fixtures often rely on machine screws to fix linear rails, motor mounts, and sensor brackets. Using a standardized machine screw size (e.g., M4, M5, ¼‑20) allows engineers to maintain interchangeability across different modules or replacement units.

-

Electronics and Electrical Enclosures

- Printed Circuit Boards (PCBs): Small machine screws (e.g., M2 or M2.5) secure PCBs to standoffs or chassis. Since electronics can be sensitive to vibration, a properly torqued machine screw keeps boards from shifting, preventing trace damage or intermittent connections.

-

Control Panels and Junction Boxes: Medium‑size machine screws (e.g., M3 to M6) fasten covers, faceplates, and internal mounting plates inside electrical enclosures. In many cases, these screws are self‑tapping into captive nuts or pre‑threaded posts, making installation quick and ensuring a clean, professional finish.

-

Automotive and Aerospace Assemblies

- Dashboard and Interior Trim: Machine screws anchor switch panels, instrument clusters, and trim pieces. Their precise thread engagement means panels stay flush without rattling—critical for both quality feel and noise reduction in vehicles.

-

Avionics Racks and Cockpit Consoles: In aviation, every fastener must meet strict vibration and temperature‑cycle requirements. Machine screws made from corrosion‑resistant alloys secure avionics components, instrument housings, and consoles, all while allowing for relatively easy maintenance access.

-

Appliances, Furniture, and Consumer Products

- Home Appliances: Washing machines, dishwashers, and refrigerators often use machine screws to fasten motors, control modules, and interior panels. Since these appliances vibrate during operation, machine screws help keep everything tight and aligned.

-

Office Equipment and Furniture: Desks with metal frames, filing cabinets, and shelving units frequently use machine screws (paired with nuts or inserted into captive nuts) for assembly. Their standardized sizes make disassembly and reassembly straightforward if you need to move or reconfigure your setup.

-

Prototyping and DIY Projects

- Hobby Robotics and 3D Printing: Makers often choose machine screws to mount motors, brackets, and 3D‑printed parts. Because you can buy matching nuts or use threaded inserts in plastic, it’s easy to adjust or rebuild prototypes without stripping out the material.

- Electronics Enclosures (Hammond Boxes, Tinker Boxes): Pre‑drilled plastic or aluminum boxes usually come with tapped holes for M3 or M4 machine screws, making it simple to secure custom PCBs, switches, and displays inside.

Why Machine Screws Are Preferred in These Applications

- Precision Fit: Machine screws have tighter thread tolerances, so they align parts precisely and resist loosening under vibration better than coarser‑thread alternatives.

- Reusability: Because they thread into metal (or brass/plastic inserts), you can remove and reinstall them multiple times without degrading the threads (provided you use the correct torque).

- Strength and Durability: Made of steel, stainless steel, or other alloys, machine screws can handle higher shear and tensile loads compared to screws meant for wood or plastic.

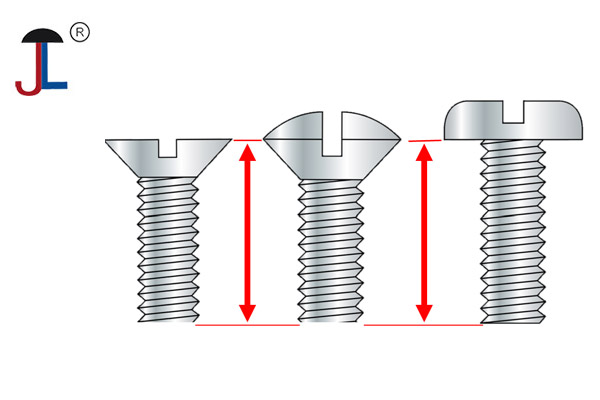

- Variety of Head Styles: From pan‑head and flat‑head to socket‑head cap screws, you can choose a profile that suits the clearance and aesthetic requirements of your project.

Key Takeaways

- Use machine screws when fastening two metal parts—especially where you have (or can create) threaded holes or use a nut.

- They’re everywhere: in industrial gear, electronics, vehicles, appliances, furniture, and DIY builds.

- Choosing the right size and material (e.g., stainless for corrosion resistance, alloy for high‑strength) ensures your assembly stays secure, even under stress or vibration.

In short, anytime you need a precise, reliable connection that you can disassemble for maintenance or adjustments, reach for machine screws. Their versatility across industries—from automotive and aerospace to home appliances and hobby electronics—makes them one of the most indispensable fasteners out there.