What is a truss head machine screw

A truss head machine screw is a type of threaded fastener characterized by a distinct head design that resembles a miniature dome or mushroom. The truss head is wider and has a lower profile compared to other screw head types such as pan head or flat head screws. It features a flat, almost horizontal top surface with a rounded, slightly curved profile that slopes down to the sides.

Key Characteristics of a Truss Head Machine Screw:

-

Low Profile and Wide Head: The truss head has a low height and a wide diameter, which allows it to distribute clamping force over a larger area. This helps prevent the screw head from digging into or damaging the material's surface.

-

Mushroom-Shaped Head: The head is rounded and protrudes out of the surface when installed, meaning it does not sit flush or countersunk in the workpiece.

-

Increased Load-Bearing Capacity: The wider head provides better load distribution, making it suitable for applications requiring a secure and durable connection.

-

Aesthetic and Functional: The design offers a clean, finished appearance while also protecting the material under the head from damage.

-

Head Recess Types: Truss head screws can come with different recess types for the screwdriver, such as Phillips, slotted, or hex drives.

Comparison to Similar Screws:

-

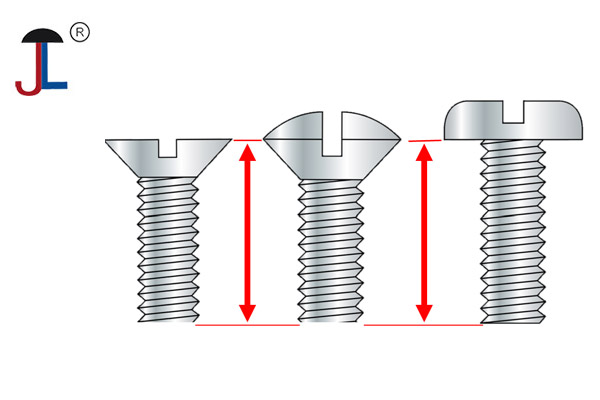

Truss Head vs Pan Head: Both have rounded, non-countersunk heads that protrude from the surface, but truss head screws have a wider and lower profile head than pan head screws. Pan head screws protrude more and have a higher profile.

-

Truss Head vs Other Heads: Truss heads are thinner and more low-profile than pan heads but are more susceptible to breaking due to the thinness of the head.

Common Uses:

Truss head machine screws are often used in aerospace and other industries where strength and load distribution are critical. Their wide head helps protect delicate surfaces and provides a strong hold without excessive protrusion.