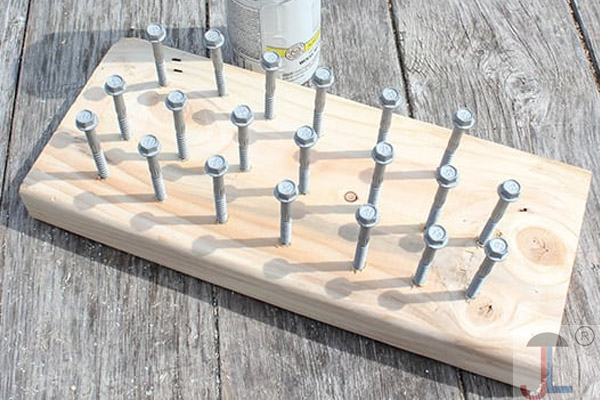

✅ Why Stainless Steel Screws Are Good for Outdoor Use

-

Corrosion Resistance: Stainless steel is naturally resistant to rust and corrosion, even in wet or humid environments, which makes it perfect for outdoor projects.

-

Durability: They’re strong and hold up well under various weather conditions — sun, rain, snow, salt air — especially if you're near the coast.

-

No Coating Needed: Unlike coated screws (like galvanized or zinc-plated ones), stainless steel screws don’t rely on a surface layer to resist rust, so even if they get scratched or worn, they still hold up.

-

Long-Term Reliability: They don’t degrade or stain wood over time like some other metals can, especially with pressure-treated lumber or hardwoods.

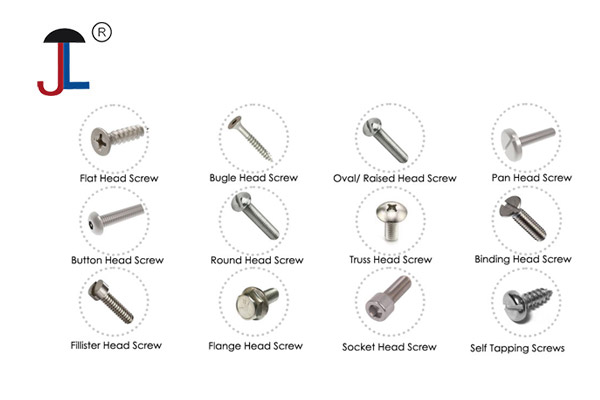

? Stainless Steel Grades for Exterior Screws

304 Stainless Steel (aka 18-8)

-

Most common grade used for general-purpose screws.

-

Good corrosion resistance in most outdoor environments — rain, humidity, etc.

-

Works well for decks, fences, garden structures, etc.

-

Not ideal near saltwater or coastal areas, as salt can eventually corrode it over time.

316 Stainless Steel (Marine Grade)

-

The king of corrosion resistance.

-

Designed to handle coastal environments, salt spray, and chemical exposure.

-

Great for dock work, boats, beachfront homes, or anywhere near the ocean.

-

More expensive, but it’s worth it if you're fighting salt.

410 Stainless Steel

-

Harder and stronger than 304/316 (better for structural strength).

-

Less corrosion-resistant, so it’s better suited for drier environments or where strength is a bigger concern than corrosion.

-

Often used for self-tapping or self-drilling screws.

? When You Might Want to Consider Alternatives

-

Cost: Stainless steel screws are more expensive than standard or coated options.

-

Strength: While plenty strong for most applications, for super heavy-duty structural work, you might need hardened steel screws — or at least make sure you're using the right grade (316 stainless is stronger and more corrosion-resistant than 304, for example).