Can you use stainless steel screws in treated lumber

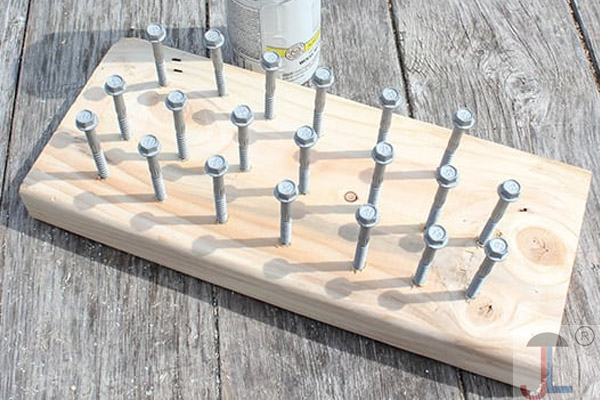

Yes, stainless steel screws are generally recommended for use with treated lumber. The chemicals used in treating lumber can cause corrosion in standard steel fasteners, leading to staining and weakening of the structure. Stainless steel is a more durable option, resistant to corrosion, and ensures the long-term integrity of your project.

Stainless steel screws provide excellent resistance to the corrosive chemicals found in treated lumber, ensuring durable and long-lasting performance in exterior applications.The American Wood Protection Association (AWPA) and major model building codes explicitly recognize stainless steel fasteners—alongside hot-dip galvanized, silicon bronze, or copper—as acceptable for use with pressure‑treated wood. In particular, Type 304 and 316 stainless steel grades are recommended for superior corrosion resistance, with Type 316 preferred in especially harsh or coastal environments.

Why Treated Lumber Requires Corrosion‑Resistant Fasteners

The chemical preservatives in treated lumber accelerate corrosion of ordinary carbon‑steel fasteners, often leading to premature failure.In cases where existing treated lumber is encountered, the only way to assure long‑term performance of connections is to use stainless steel fasteners and connectors.

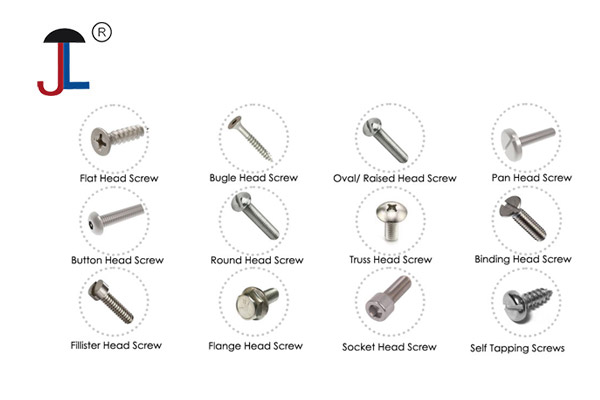

Stainless Steel Screws: Grades and Performance

The most common stainless steel grades used for outdoor construction are 304 and 316, offering superior corrosion resistance compared to lower grades.Type 316 stainless steel is particularly recommended for ground‑contact and coastal applications due to its enhanced resistance to chlorides and preservative chemicals.

Best Practices and Alternatives

For above‑ground applications in less corrosive environments, hot‑dip galvanized fasteners conforming to ASTM standards remain a cost‑effective alternative.Other corrosion‑resistant materials such as silicon bronze and copper are permitted by model building codes but generally come at a higher cost.